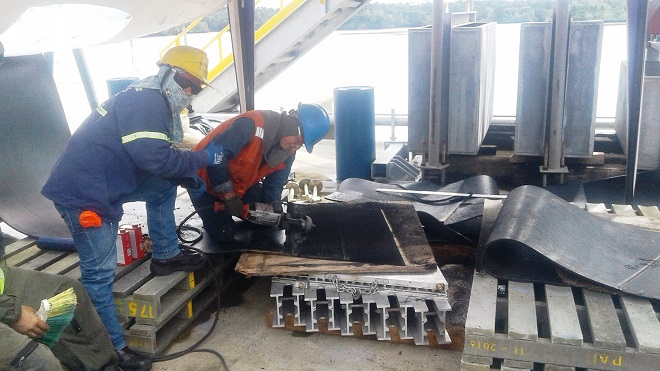

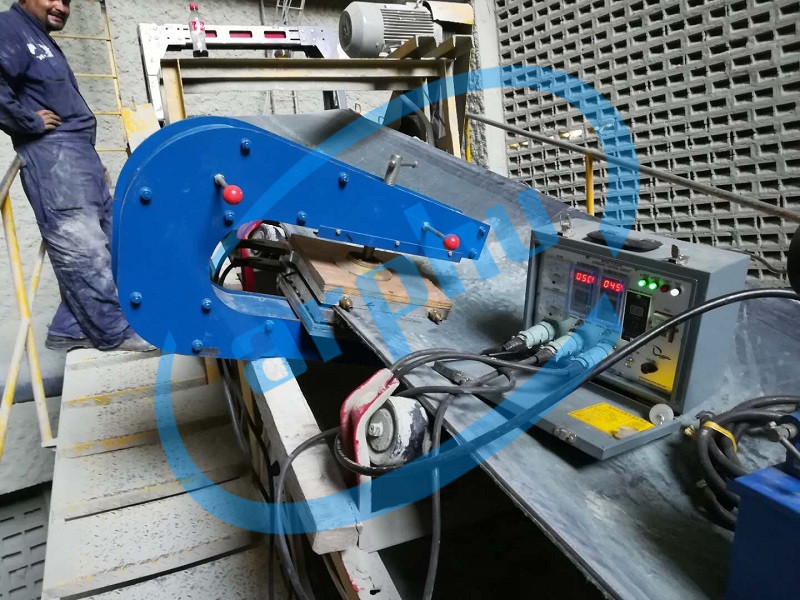

Conveyor Belt Vulcanizer works at site

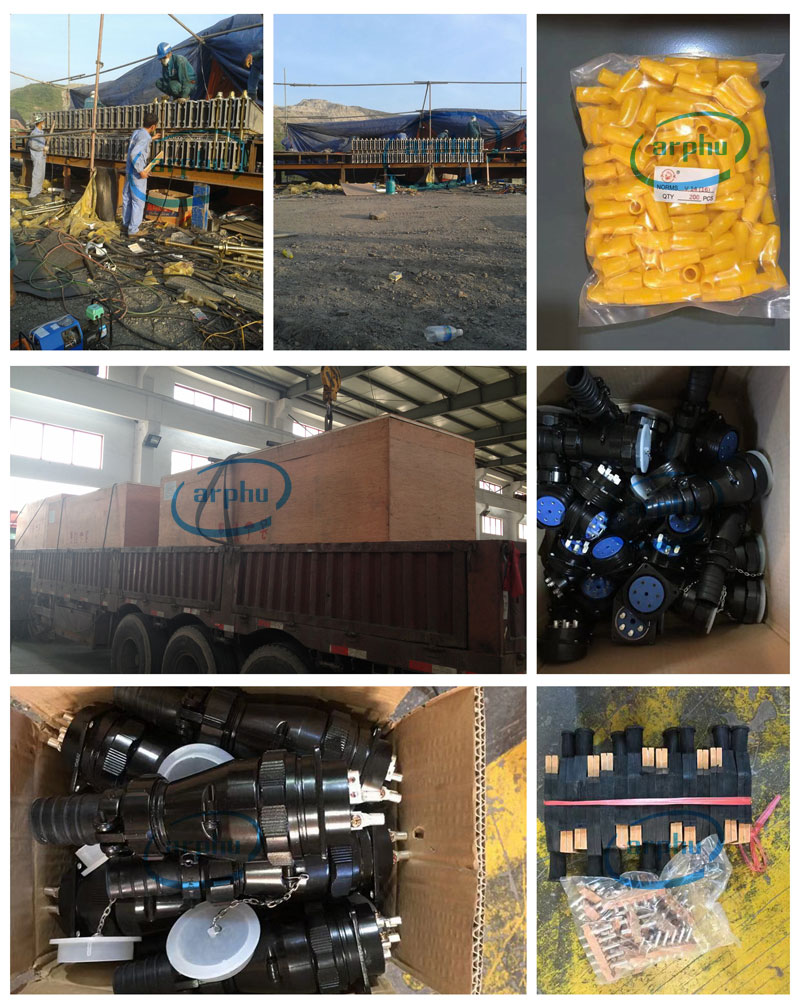

Suzhou Arphu Industrial Co., Ltd, exported four sets of conveyor belt vulcanizers to Colombia, the model is DLCBV-800*830, DLCBV-1000*830, DLCBV-1350*1000 and DLCBV-1500*1000.

After testing and installation at site, customers comment that the conveyor belt vulcanizers are pretty good quality, and splicing is very good. And they share some pictures with us about the operation of conveyor belt vulcanizers.

We'd like to share our happiness to hear from the feedback from our customers, best wishes for you.