Safety Precautions as Operation of Conveyor Belt Vulcanizer

Safety Precautions as Operation of Conveyor Belt Vulcanizer

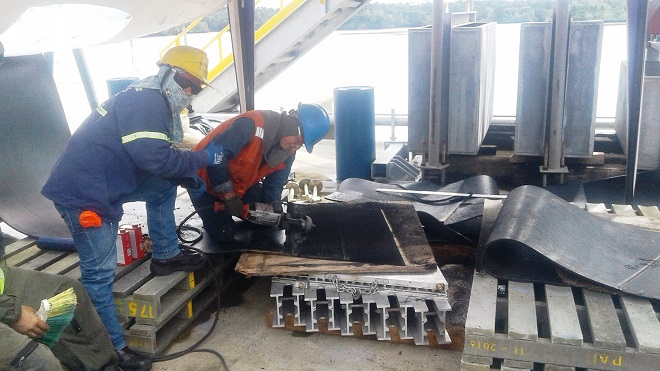

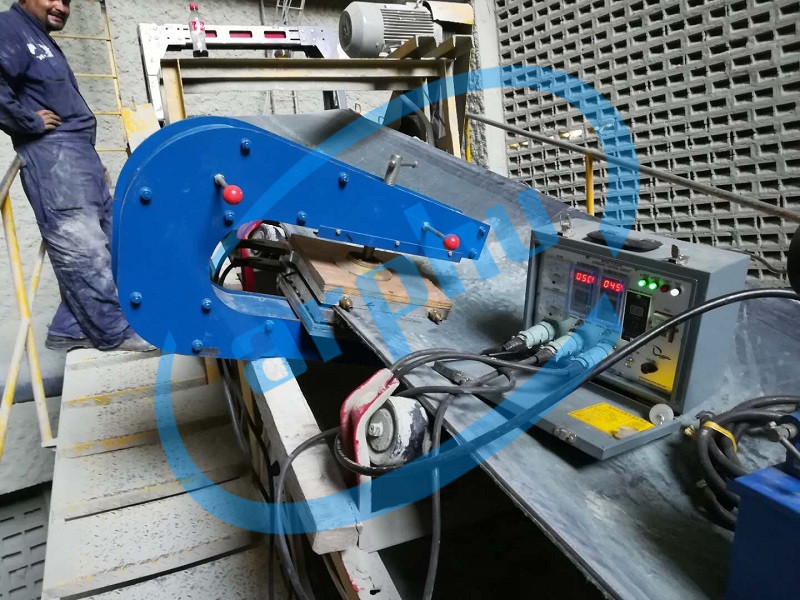

Conveyor belt vulcanizer belongs to industrial electroheating equipment, safety precautions are needed in the process of operation of vulcanizing presses.

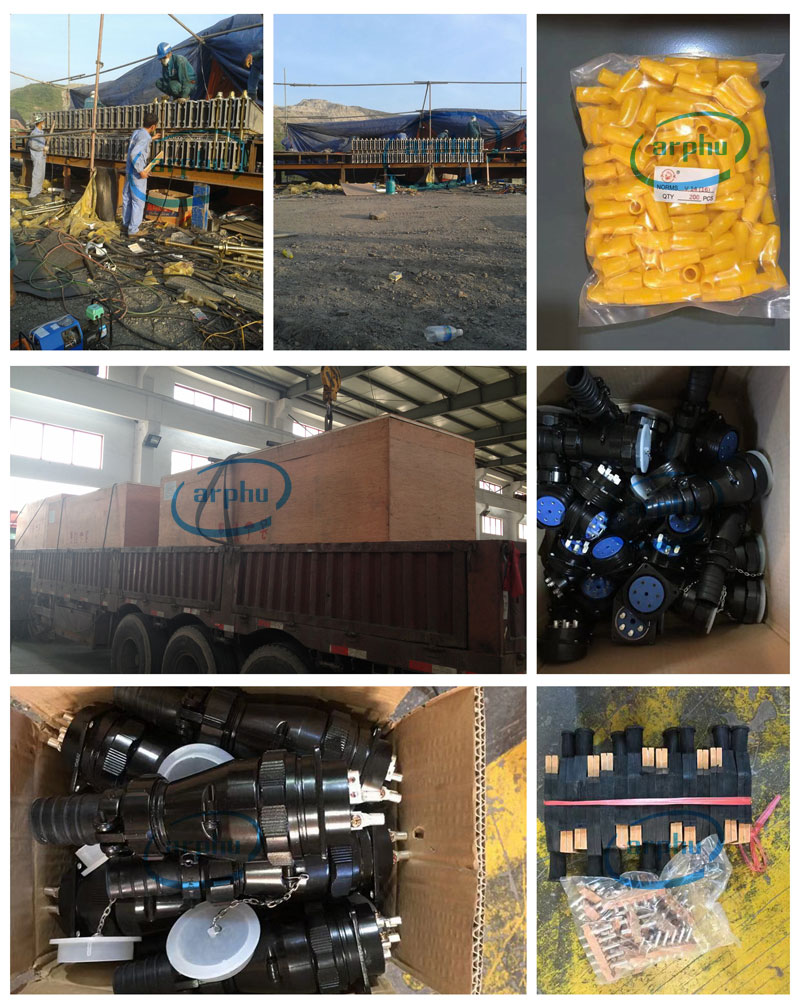

1.Please prepare 2 sets of 7 kgs powder fire extinguishers, sand and water., etc;

2.All the electrical equipment must have reliable ground protection, check all the cables;

3.Keep gasoline, rubber sheet, etc far away the fire seat, and guards in position.

4.In the process of operation of conveyor belt vulcanizer, workers must guard in position, after vulcanization finished, cut off the power and clear working site, disassemble conveyor belt vulcanizer, repairing tools and splicing tools to ensure store conveyor belt vulcanizer or vulcanizing presses in dry and cool environment.