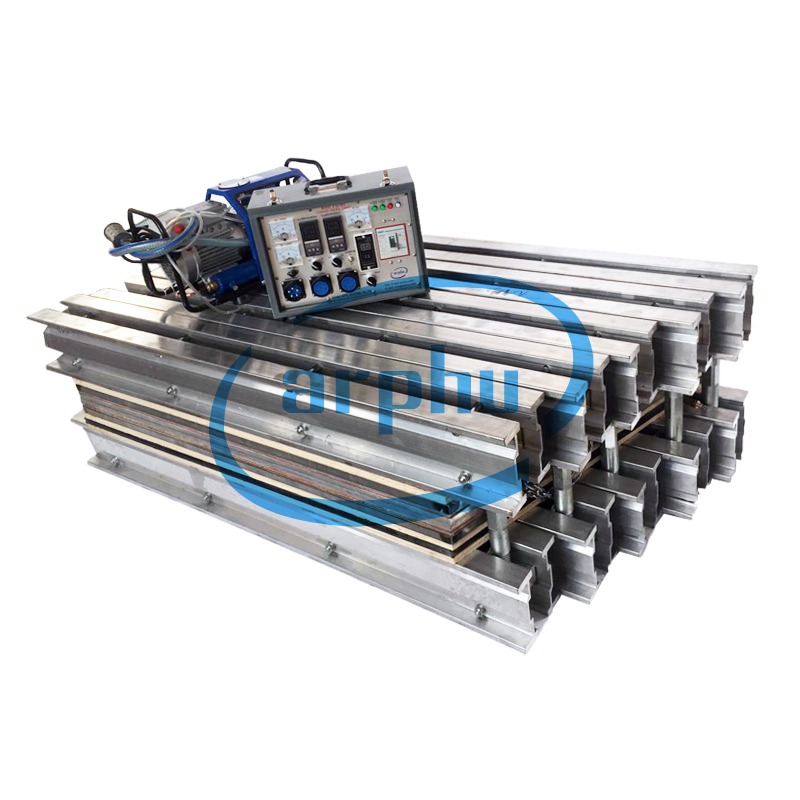

Heavyweight Sectional Conveyor Belt Vulcanizer

Arphu specializes in the designing and manufacturing quality conveyor belt vulcanizers, conveyor belt maintenance materials, hot splicing tools and equipment to power plant, steel plant, cement plant, mine, port, chemical industry etc. Besides supplies the conveyor belt vulcanizing press, Arphu can also supply a series of auxiliary tools to the conveyor system.When the on-site splicing is correctly done with the portable belt vulcanizing machine, the belt joints shall be smooth, belt strength shall be reach over 90% of the original belt, through hot splicing it shall reduce the abrasion of roller and extend the conveyor and belt's working life.

Heavyweight Sectional Conveyor Belt Vulcanizer With E Type Cross Bar

Conveyor Belt Vulcanizer is widely used in port, mine, milling factory, power plant, cement company., etc, it's used to repair and splice conveyor belt, such as EP belt, Steel cord belt, etc.

The SVP type conveyor belt vulcanizer from arphu is the preferred heavyweight sectional vulcanizing press. Offering portability and great size versatility for coverage of all splice lengths, whether fabric, EP or steel cord belt. These presses disassemble into individual components for ease of transport and maneuverability when splicing in limited space or remote locations. Components are lightweight and easy to assemble. The modular design also allows for an increase in splice length or belt width by adding another section.

MAIN TECHNICAL PARAMETERS:

- 1. Working Pressure: 0.7-1.5 MPa (100 psi to 220 psi) and custom design for your special need;

- 2. Vulcanization temperature: 145°C or as per actual requirement;

- 3. Difference in surface temperature of vulcanized plate: ± 3°C;

- 4. Heating up time ( from normal temperature to 145°C )<30 minutes;

- 5. Voltage: 220V/ 380V/415V/440V/480V/550V/660V, 50/60Hz; custom designed to voltage phase and cycle;

- 6. Temperature Controller adjustment range: 0 to 199°C;

- 7. Timer adjustment range: 0 to 99 minutes.

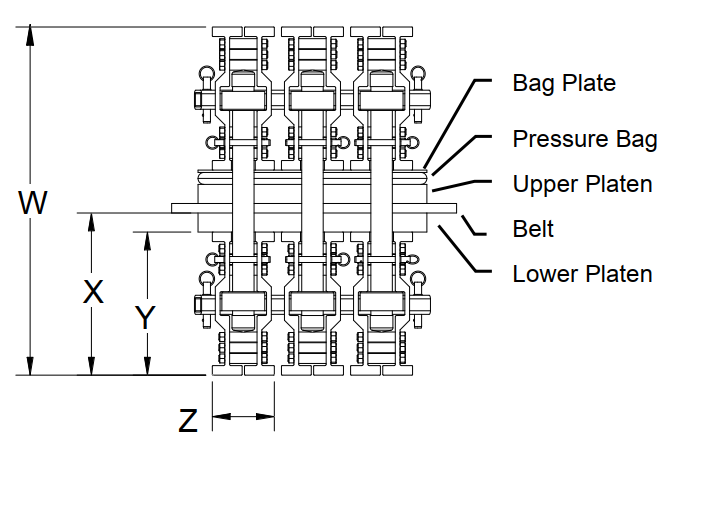

HEATING PLATENS

- Each sectional press is constructed with aluminum flexible platens that contour to the conveyor belt surface during splicing;

- Platens are individually designed and include BUILT-IN cooling system, and BUILT-IN temperature sensor;

- Sturdy and shock-proof plug and sockets to enhance vulcanizing press durability.

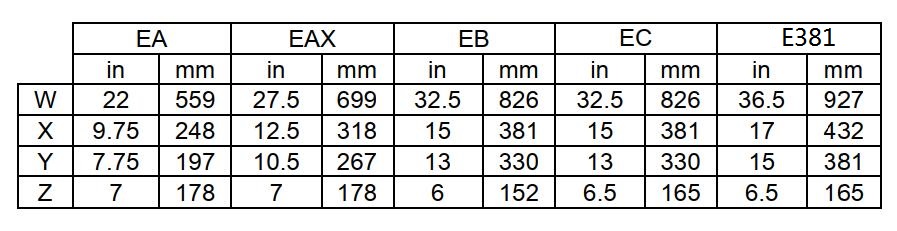

CROSS BARS

- Bars are available in various profiles and lengths and height to provide a custom solution for your needs;

- Bars are specially designed by aviation aluminum alloy and manufactured out of quality extruded aluminum alloy;

- Various bolt and nut styles complement each bar type and provide a secure, pressurized splice.

PRESSURE/COOLING

- Pneumatic or water pressure up to 1.5 MPa or 220 psi;

- Cooling time within 10 mins from 145 ° C to 60°C.

SUITABLE PUMPS: Manual pump and Electric pump for your prefered

choosen

- The pumps include gauges for fluid level and pressure

- Extra reservoirs can be easily added for larger presses

Cooling options are also available.